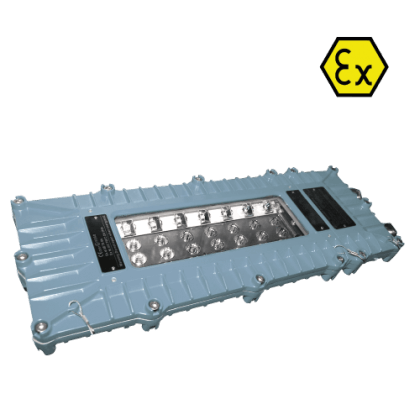

ATEX Lights designed for

PURPOSE

With a wattage range of 80W to 150W, the Somerville Series is designed to be a general purpose ATEX Rated (Zone 2) floodlight. Features include:

Mounting: The Somerville line-up offers users 4 Installation options. The standard universal mounting bracket allows 360° rotation within cradle. Alternatives include a surface-mounting bracket, pole slip fitters for area lighting application, and pendant loops for ATEX high bay usage and reduced fitting variation across site.

- Heat Dissipation: The Somerville series has the wide ambient usage tolerance of -40° to 55°C. LED chips spacing and the driver being placed externally on the back of the light fitting provides excellent heat dissipation and lower junction temperatures resulting in a lumen maintenance of L70 ≥ 120,000 Hours.

- Environmental Protection: It offers IP66 protection by using aluminium body that comes with corrosion resistant paint finish - Salt spray testing reports available.

- Impact Resistance: Risk of early failure is mitigated by using a shock and vibration-resistant aluminium alloy housing capable of withstanding an impact of up to 10 Joules (IK10). A tempered glass lens provides impact resistance up to IK08. An optional stainless steel guard increases this to IK10.