How can Kellwood Lighting help?

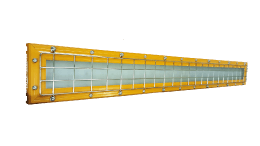

- Robust Light Fittings - our inspection pit lights are powder-coated with high IK (impact) ratings for increased product longevity.

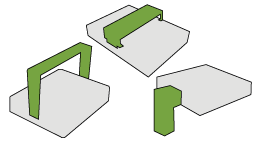

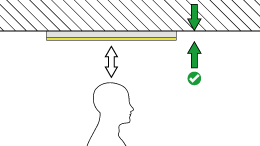

- Low Profile Lights - compact luminaires with multiple mounting options (suitable for recessed wall cavity installation) to maximise workspace.

- Emergency Lighting - we can provide emergency lighting solutions for inspection pits, as well as general lighting solutions.

- Energy Saving - High efficiency LED light engines minimise energy consumption, and electricity bills.

- Lighting Design - our lighting design team have the knowledge and experience to provide inspection pit lighting schemes to meet SLL (CIBSE) requirements.

- Smart Controls - optional smart controls can further reduce energy consumption through integrated microwave sensors and DALI dimming.

Please refer to our Hazardous Areas page for information relating to lighting other areas including tank farms, distilleries, and paint shops.