Lighting Challenges in Oil Refineries

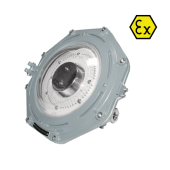

Oil refineries present some of the most demanding lighting environments. Operators must balance visibility for safety-critical tasks with compliance to ATEX and IECEx standards governing explosive atmospheres. Lighting must withstand extreme temperatures, corrosive conditions, and long operating hours while minimising maintenance downtime.

Kellwood Lighting delivers ATEX-certified, durable, and low-maintenance luminaires engineered for refinery applications. Our team works with end-users, consultants, and contractors to design compliant lighting schemes that support operational efficiency and safety. From process areas and control rooms to external tank farms and walkways, we ensure illumination meets the required lux levels and sector-specific regulations.