ATEX Tank Lighting

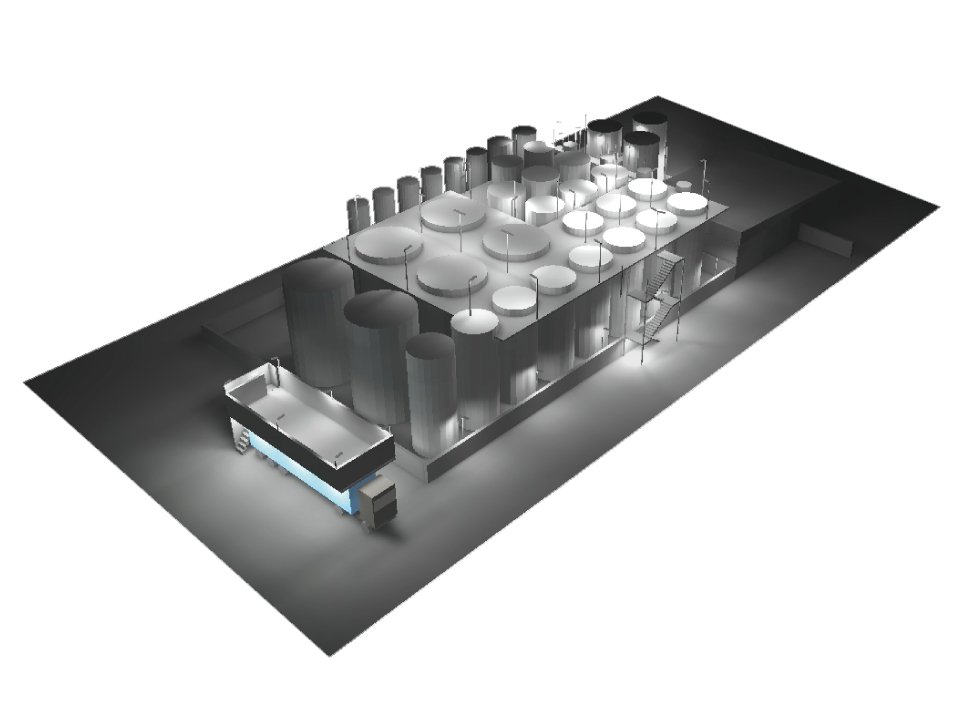

Distilleries, petrochemical companies, and chemical processors, all require mass storage and processing of hazardous liquids and gases - typically in Tank Farms. Volatility of product and the associated risks can vary; therefore the initial design requirement is to establish the Zone rating(s) of the tank farm.

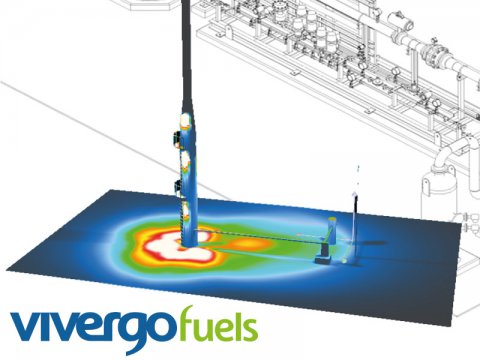

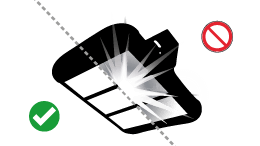

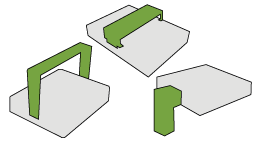

After this, the lighting design process has a common process - establish the tasks taking place, and design to meet industry established lux levels, uniformity, etc. Kellwood has the product range and knowledge to support you.